1. It records the total water consumption flowing through the tap water pipeline. It cannot be used for metering sewage or corrosive liquids.

2. This water meter adopts a removable structure: the water meter does not need to be removed from the pipeline, and the movement can be pulled out for repair or replacement.

3. The measuring mechanism has good universality, which reduces the need for spare parts. It also features low pressure loss and a long service life.

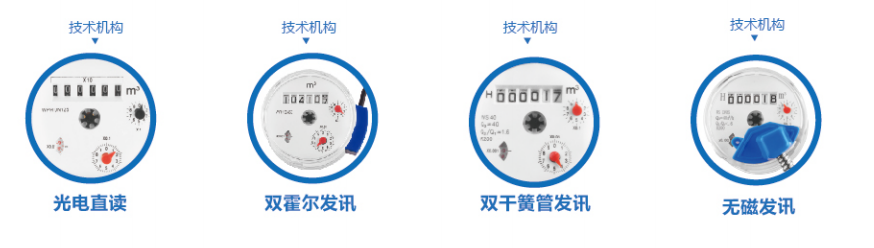

4. It can be reserved for magnetic or non-magnetic signaling pointers. Various remote transmission devices can be configured according to different needs to realize the remote meter reading function.

- Technical Parameters

- About us

- Contact us

External dimensions and weight

| Model | Caliber |

Long |

Tall |

Tall |

Connection method |

Weight |

||

|

mm |

Flange outer diameter |

Bolt hole center circle diameter |

Number of connecting bolts |

kg |

||||

|

LXLC(Y)-50/50F |

50 |

200 |

256/245(F) |

400 |

165 |

125 |

4xM16 |

12.0 |

|

LXLC(Y)-65/65F |

65 |

200 |

266/255(F) |

400 |

185 |

145 |

4xM16 |

13.5 |

|

LXLC(Y)-80/80F |

80 |

225 |

276/265(F) |

400 |

200 |

160 |

8xM16 |

14.5 |

|

LXLC(Y)-100/100F |

100 |

250 |

286/275(F) |

400 |

220 |

180 |

8xM16 |

15.5 |

|

LXLC(Y)-125/125F |

125 |

250 |

301/290(F) |

400 |

250 |

210 |

8xM16 |

24.5 |

|

LXLC(Y)-150/150F |

150 |

300 |

345/335(F) |

500 |

285 |

240 |

8xM20 |

32.0 |

|

LXLC(Y)-200/200F |

200 |

350 |

373/365(F) |

500 |

340 |

295 |

8xM20 |

41.0 |

|

LXLC(Y)-250/250F |

250 |

450 |

493/485(F) |

710 |

395 |

350 |

12xM20 |

83.0 |

|

LXLC(Y)-300/300F |

300 |

500 |

516/505(F) |

730 |

445 |

400 |

12xM20 |

99.0 |

|

LXLC(Y)-400/400F |

400 |

600 |

631/620(F) |

830 |

565 |

515 |

16xM24 |

163.0 |

|

LXLC(Y)-500/500F |

500 |

800 |

739/730(F) |

930 |

670 |

620 |

20xM24 |

270.0 |

|

LXLC(Y)/R-50 |

50 |

200 |

256 |

400 |

165 |

125 |

4xM16 |

12.0 |

|

LXLC(Y)/R-65 |

65 |

200 |

266 |

400 |

185 |

145 |

4xM16 |

13.5 |

|

LXLC(Y)/R-80 |

80 |

225 |

276 |

400 |

200 |

160 |

8xM16 |

14.5 |

|

LXLC(Y)/R-100 |

100 |

250 |

286 |

400 |

220 |

180 |

8xM16 |

15.5 |

|

LXLC(Y)/R-125 |

125 |

250 |

301 |

400 |

250 |

210 |

8xM16 |

24.5 |

|

LXLC(Y)/R-150 |

150 |

300 |

345 |

500 |

285 |

240 |

8xM20 |

32.0 |

|

LXLC(Y)/R-200 |

200 |

350 |

373 |

500 |

340 |

295 |

8xM20 |

41.0 |

Note:

1) The flange connection shall be in accordance with the specifications of GB/T172416-2008/XG-2011 PN10 integral cast iron flange dimensions, and special specifications shall be proposed when ordering.

2) The height G dimension is necessary for disassembling the movement. The external dimensions and weight are for reference only, and the actual product shall prevail.

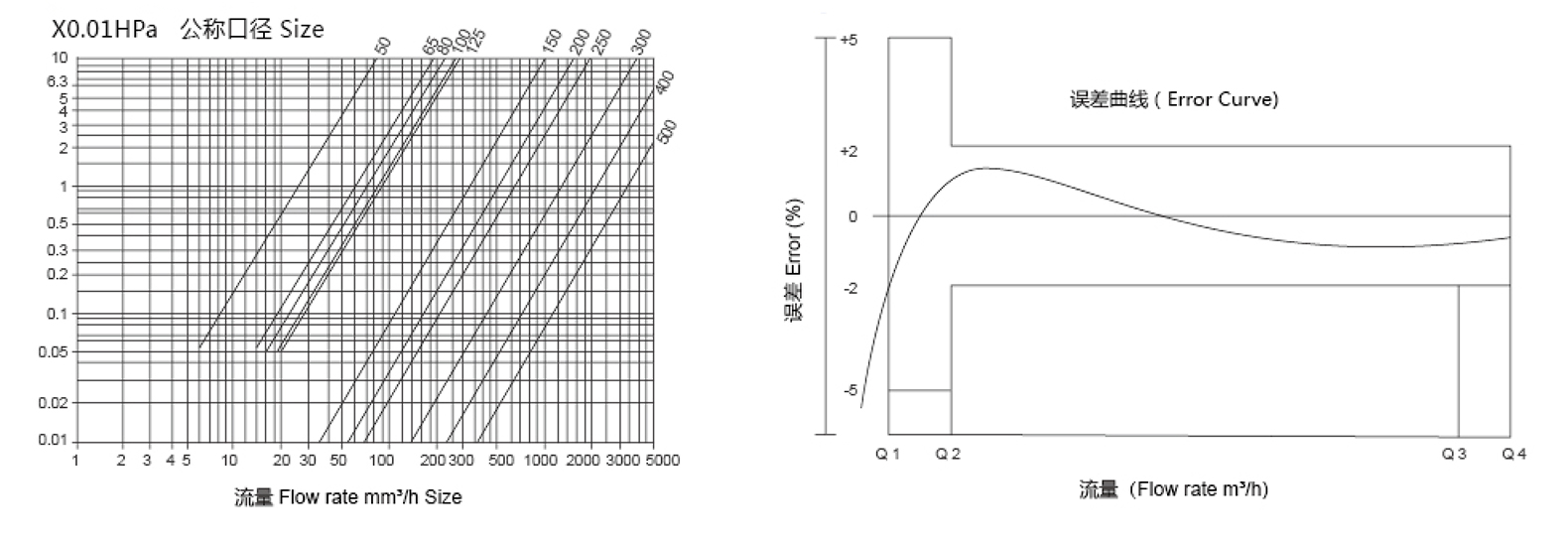

Pressure loss curve / Performance error curve

Technical indicators

1. Flow parameters

|

Caliber |

Q3/Q1 |

Overload flow rate |

Common traffic |

Boundary flow |

Minimum flow rate |

Minimum reading |

Maximum reading |

|

m³/h |

L/h |

m³ |

|||||

|

50 |

100 |

50 |

40 |

640.0 |

400.0 |

0.001 |

999999 |

|

80 |

800.0 |

500.0 |

|||||

|

50 |

1280.0 |

800.0 |

|||||

|

65 |

100 |

78.75 |

63 |

1008.0 |

630.0 |

||

|

80 |

1260.0 |

787.5 |

|||||

|

50 |

2016.0 |

1260.0 |

|||||

|

80 |

100 |

78.75 |

63 |

1008.0 |

630.0 |

||

|

80 |

1260.0 |

787.5 |

|||||

|

50 |

2016.0 |

1260.0 |

|||||

|

100 |

100 |

125 |

100 |

1600.0 |

1000.0 |

||

|

80 |

2000.0 |

1250.0 |

|||||

|

50 |

3200.0 |

2000.0 |

|||||

|

125 |

100 |

200 |

160 |

2560.0 |

1600.0 |

||

|

80 |

3200.0 |

2000.0 |

|||||

|

50 |

5120.0 |

3200.0 |

|||||

|

150 |

100 |

312.5 |

250 |

4000.0 |

2500.0 |

0.01 |

9999999 |

|

80 |

5000.0 |

3125.0 |

|||||

|

50 |

8000.0 |

5000.0 |

|||||

|

200 |

100 |

500 |

400 |

6400.0 |

4000.0 |

||

|

80 |

8000.0 |

5000.0 |

|||||

|

50 |

12800.0 |

8000.0 |

|||||

|

250 |

100 |

787.5 |

630 |

10080.0 |

6300.0 |

0.1 |

99 999999 |

|

80 |

12600.0 |

7875.0 |

|||||

|

50 |

20160.0 |

12600.0 |

|||||

|

300 |

100 |

1250 |

|

16000.0 |

10000.0 |

||

|

80 |

1000 |

20000.0 |

12500.0 |

||||

|

50 |

|

32000.0 |

20000.0 |

||||

|

400 |

100 |

2000 |

1600 |

25600.0 |

16000.0 |

||

|

80 |

32000.0 |

20000.0 |

|||||

|

50 |

51200.0 |

32000.0 |

|||||

|

500 |

100 |

3125 |

2500 |

40000.0 |

25000.0 |

||

|

80 |

50000.0 |

31250.0 |

|||||

|

50 |

80000.0 |

50000.0 |

|||||

Maximum allowable error:

a) The maximum allowable error in the low zone (QisQ<Q2) is+5%; b) The maximum allowable error for high zone (QQQ4) is 2%.

2. Parameters

|

Project content |

parameter |

|

Temperature rating |

T30/90 |

|

Pressure rating |

MAP16 |

|

Flow field sensitivity level |

U0/D0 |

|

Pressure loss level |

△pl6 |

|

Accuracy class |

level 2 |

Note: The temperature level of LXLC (Y)/R-50~200 is T30/90.

Remote transmission scheme

About Ningbo Water Cube Instrument Technology Co., Ltd.

Ningbo Water Cube Instrument Technology Co., Ltd. is China DN400-600 Horizontal Removable Water Meter Manfacturers and Wholesale DN400-600 Horizontal Removable Water Meter Suppliers specializing in producing large-diameter water meters and water meter movements, including product design and development, mold manufacturing, injection molding processing, and assembly and verification. The industrial chain is complete and we have long-term cooperation with many domestic enterprises. Enterprise purpose: quality first, reputation first. Warmly welcome industry colleagues to visit and provide guidance.

-

Industry Standard

-

9+ Industrial Experience

-

Exported To Many Countries

-

7*24 Hours Customer Service

Recent News

Does the WPH horizontal spiral wing water meter offer convenient connection interfaces?

26-Feb-2026

Does the WS vertical spiral wing water meter have anti-backflow, anti-impact design, or leakage protection mechanisms?

19-Feb-2026

Are vertical water meters prone to wear, jamming, leaks, or reading drift?

12-Feb-2026

Does the WI irrigation water meter have corrosion-resistant and rust-proof design features, making it suitable for different water qualities?

05-Feb-2026

What are the main features and advantages of the WS vertical spiral wing water meter?

22-Jan-2026

عربى

عربى