Structural Advantages of the Horizontal Detachable Water Meter

The

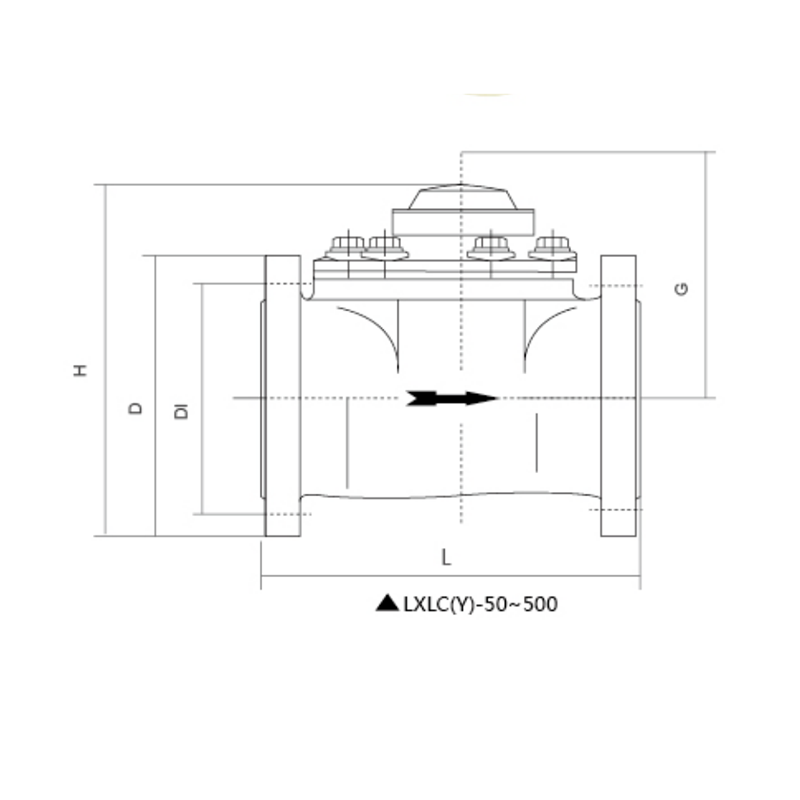

Horizontal Detachable Water Meter features a detachable design that allows the meter’s movement to be removed from the pipeline independently of the housing, significantly reducing operational interruptions. This design provides clear advantages for maintenance planning and operational efficiency. By allowing the movement to be pulled out without dismantling the entire meter, maintenance personnel can access the internal mechanism for inspection, calibration, or replacement of worn parts without shutting down the water system. This is particularly useful in large-diameter pipelines, where halting the flow could disrupt industrial processes or municipal water distribution. Ningbo Water Cube Instrument Technology Co., Ltd. designed this detachable system to ensure that maintenance procedures are streamlined, requiring less manpower and less time to complete routine inspections or repairs. The mechanism’s modularity reduces the risk of errors during reassembly since the movement can be tested independently before reinsertion, ensuring consistent operational accuracy once the meter is returned to service. The detachable design enhances safety because maintenance personnel can work on the isolated movement without exposure to high-pressure flow, reducing the likelihood of accidents. The design also simplifies spare part management, as the movement can be standardized across multiple meter sizes, allowing Ningbo Water Cube Instrument Technology Co., Ltd. to provide consistent replacement components for DN50–DN500 meters. In practice, this approach reduces inventory complexity and supports cost-effective maintenance strategies. Overall, the detachable structure of the Horizontal Detachable Water Meter demonstrates the integration of practical engineering with long-term operational reliability, reflecting Ningbo Water Cube Instrument Technology Co., Ltd.’s commitment to providing a robust, user-friendly solution for large-diameter water metering applications.

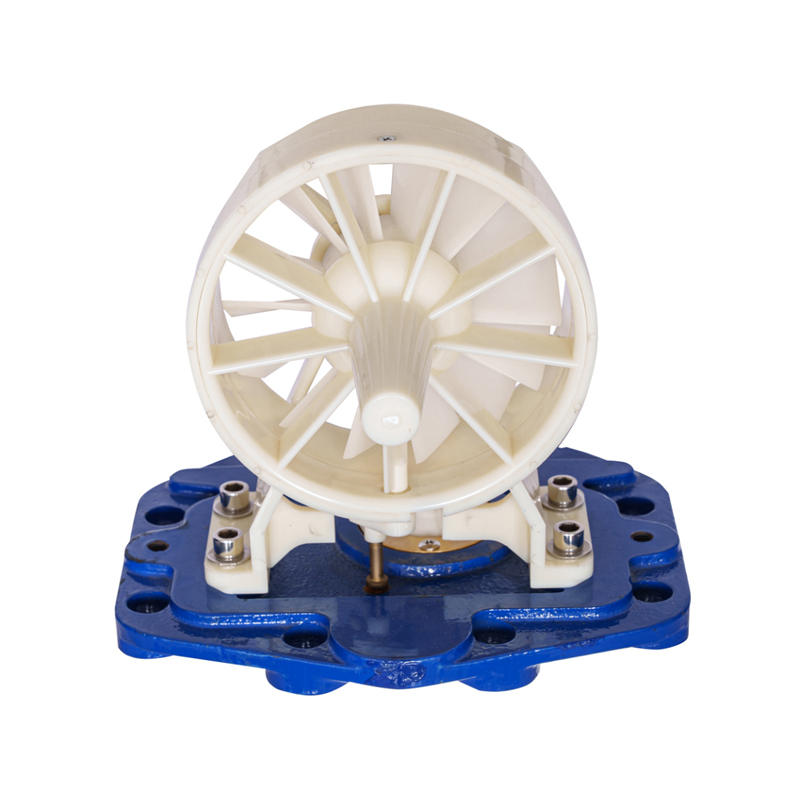

The Horizontal Detachable Water Meter is engineered with a modular construction, ensuring that key components, including the measuring mechanism, impellers, gears, and housing sections, can be independently removed, replaced, or upgraded. This modularity provides considerable operational and logistical advantages, reducing downtime and maintenance complexity. Ningbo Water Cube Instrument Technology Co., Ltd. emphasizes that modular design supports standardization of spare parts, which allows maintenance teams to keep a smaller inventory while addressing multiple meter sizes and configurations. Each component is manufactured to precise specifications, ensuring that parts can be interchanged without custom adaptation, which reduces the likelihood of errors during assembly and facilitates faster repair cycles. The modular architecture also supports scalability and upgrades; for example, advanced measurement modules or digital readout mechanisms can be integrated into existing meters without requiring replacement of the entire unit. This adaptability makes the Horizontal Detachable Water Meter suitable for evolving water management requirements. Furthermore, modular construction contributes to the overall structural integrity of the meter by allowing reinforcement in critical areas, such as bearing housings or flow channels, while keeping the total unit lightweight and manageable. This balance between durability and practicality ensures that installation and service procedures are efficient. Ningbo Water Cube Instrument Technology Co., Ltd. incorporates rigorous quality control in the production of each modular component, ensuring consistent performance and long service life across all DN50–DN500 meter sizes. The modular design not only improves operational reliability but also reduces long-term maintenance costs by simplifying access to individual parts and minimizing the risk of unnecessary replacements, positioning the Horizontal Detachable Water Meter as a practical and efficient solution for large-scale water metering projects.

The Horizontal Detachable Water Meter features a housing constructed from high-quality metals and polymers designed to withstand mechanical stress, water pressure, and long-term exposure to tap water environments. Ningbo Water Cube Instrument Technology Co., Ltd. selects materials based on strength, durability, and resistance to corrosion, ensuring that the meter maintains structural integrity under continuous operation. Stainless steel components and coated alloys are used for load-bearing sections, preventing deformation or leaks in high-pressure pipelines, while specialized polymers and elastomers are applied to moving parts and seals to resist wear and chemical interactions with water minerals. This combination of materials allows the meter to maintain performance over long service periods without frequent replacement of the housing or internal supports. The robust housing also provides mechanical stability during installation and operation, accommodating potential vibrations or pressure fluctuations within the pipeline. Ningbo Water Cube Instrument Technology Co., Ltd. emphasizes that the housing’s durability is paired with precision engineering to minimize any contribution to pressure loss, ensuring accurate measurement even in high-flow conditions. The corrosion-resistant structure supports maintenance efficiency by reducing the frequency of cleaning or surface treatment requirements, allowing the detachable movement to be accessed without concern for damage to the meter body. Long-term field performance of the Horizontal Detachable Water Meter demonstrates that robust housing and corrosion-resistant design contribute significantly to reducing operational disruptions, minimizing maintenance expenses, and extending service life, establishing it as a reliable option for large-diameter water metering in municipal and industrial systems managed by Ningbo Water Cube Instrument Technology Co., Ltd.

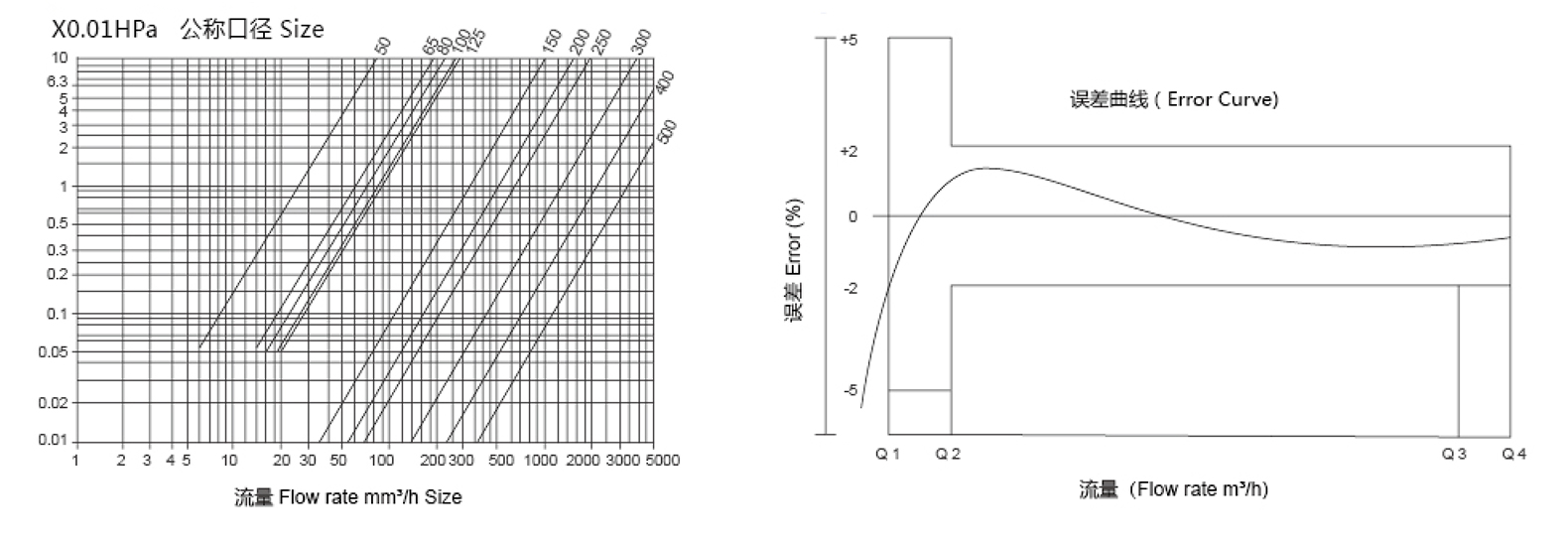

The Horizontal Detachable Water Meter is designed with an internal flow path optimized to reduce turbulence, minimize pressure loss, and improve measurement accuracy. The internal channels are carefully engineered to guide water through the meter smoothly, maintaining laminar flow conditions that enhance precision. Ningbo Water Cube Instrument Technology Co., Ltd. has applied computational fluid dynamics (CFD) modeling and extensive testing to ensure the flow path design reduces energy losses while supporting a broad range of flow rates typical in DN50–DN500 pipelines. The meter’s internal structure ensures that the impeller or piston operates consistently, even under variable flow conditions, minimizing error and providing reliable readings across low, medium, and high flow rates. The optimization also contributes to long-term durability because reduced turbulence decreases wear on moving components, such as gears and bearings, and prevents unnecessary stress on seals. By controlling the flow path, the meter also mitigates the effects of air bubbles, sediment, or minor particulates that could interfere with measurement in conventional meters. This level of hydraulic efficiency reduces the load on pumping systems, as minimal energy is lost in the meter, which is particularly advantageous for municipal and industrial networks where energy conservation is a priority. Ningbo Water Cube Instrument Technology Co., Ltd. integrates these design principles into every Horizontal Detachable Water Meter to ensure that us can rely on consistent, accurate readings and maintain system performance with minimal intervention. Overall, the optimized flow path is a structural feature that combines accuracy, energy efficiency, and reliability, reflecting the company’s focus on practical and long-lasting engineering solutions for large-diameter water systems.

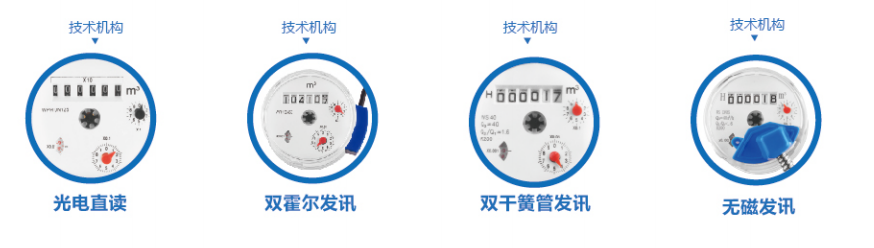

The Horizontal Detachable Water Meter is equipped with a universal measuring mechanism designed for versatility and durability. Ningbo Water Cube Instrument Technology Co., Ltd. has engineered the mechanism to function across a wide range of pipeline diameters from DN50 to DN500, allowing us to standardize operations across multiple sites without the need for multiple meter models. The universal mechanism ensures precise measurement of water consumption regardless of varying flow rates, which is critical for municipal water distribution and industrial applications where consistency directly impacts billing accuracy and resource management. The mechanism is designed to reduce the number of spare parts required because its components are compatible across multiple meter sizes, simplifying maintenance and inventory management. Bearings, gears, and other moving parts are manufactured from high-performance alloys and treated to resist wear, friction, and water-borne contaminants, ensuring long-term operational reliability. The mechanism’s design also supports rapid maintenance or replacement due to its compatibility with the detachable structure of the meter, which allows us to remove and service the measuring unit independently of the housing. Ningbo Water Cube Instrument Technology Co., Ltd. integrates rigorous quality control procedures during the production and assembly of the measuring mechanism, ensuring consistency, accuracy, and durability in all units. The universal design reduces the likelihood of measurement errors caused by flow disturbances or mechanical wear, and it provides a future-proof platform for upgrades or integration with smart water metering technologies. By combining precision, adaptability, and ease of service, the universal measuring mechanism reinforces the structural advantages of the Horizontal Detachable Water Meter and supports long-term operational efficiency.

The Horizontal Detachable Water Meter utilizes advanced materials to enhance structural integrity, durability, and resistance to environmental factors. Ningbo Water Cube Instrument Technology Co., Ltd. selects high-performance metals, polymers, and elastomers to construct the housing, internal components, and seals, ensuring the meter withstands pressure, vibration, and chemical interactions typical of tap water pipelines. Metals such as stainless steel or coated alloys are used for load-bearing elements and flanges, providing structural strength and resistance to deformation under high-pressure conditions. High-quality polymers are applied to moving components like impellers, gears, and pistons to reduce friction, minimize wear, and maintain accuracy over extended periods. Seals and gaskets are manufactured from resilient elastomers capable of maintaining their properties under continuous exposure to water, temperature fluctuations, and mechanical movement. The combination of materials also contributes to corrosion resistance, which reduces the frequency of maintenance interventions and ensures long-term stability of the meter. By integrating advanced materials, Ningbo Water Cube Instrument Technology Co., Ltd. ensures that the Horizontal Detachable Water Meter maintains consistent measurement accuracy, low pressure loss, and reliable performance in a variety of operating conditions. This approach also supports environmental sustainability because the materials are chosen for durability, reducing the need for replacements and minimizing waste. Advanced material integration reinforces the meter’s detachable structure, ensuring that both the housing and the removable movement maintain operational integrity during installation, service, or repair. This structural advantage not only increases the service life of the meter but also provides confidence that us can rely on the meter for critical water monitoring in municipal and industrial applications.

عربى

عربى