Structural Design Advantages of the WPH DN50–DN200 Horizontal Detachable Spiral Wing Water Meter

The

WPH DN50–DN200 Horizontal Detachable Spiral Wing Water Meter is engineered around a structural philosophy that balances durability, hydraulic precision, and maintenance accessibility. The fundamental concept is that a water meter must integrate the mechanical, fluidic, and material design elements in a coordinated framework to maintain consistent performance over long-term operation. By carefully calibrating flow channels, impeller geometry, shaft alignment, and casing rigidity, the meter achieves operational stability across varying flow rates. Ningbo Water Cube Instrument Technology Co., Ltd., with its complete industrial chain including product design, mold manufacturing, injection molding, and assembly, ensures that every structural component meets exacting standards and aligns with the overall engineering intent. The structural philosophy prioritizes reducing internal resistance to flow, minimizing mechanical friction, and enabling precise torque transfer from the fluid to the impeller. This design allows the meter to maintain consistent rotation even at low flow conditions and to accurately measure high flow rates without introducing measurement error. Additionally, the modular design philosophy ensures that maintenance, calibration, or replacement of the internal movement can occur without compromising structural integrity. This integrated approach allows the meter to withstand external installation forces, internal pressure fluctuations, and environmental challenges while maintaining measurement accuracy, making the design both robust and adaptable to varied water supply systems.

The external case of the WPH DN50–DN200 Horizontal Detachable Spiral Wing Water Meter serves as both a structural protector and a precision alignment base for internal components. Its design incorporates reinforcement ribs and contouring that distribute stress uniformly along the body, mitigating deformation under varying pressure conditions. The rib placement is calculated using finite element analysis, simulating real-world pressure fluctuations, pipeline vibrations, and thermal expansion scenarios to ensure structural stability. The casing is made from a metallurgically optimized alloy that balances corrosion resistance, mechanical strength, and thermal stability. Wall thickness is graded to provide maximum rigidity at stress points while reducing unnecessary material in low-load regions, improving both weight efficiency and ease of installation. Ningbo Water Cube Instrument Technology Co., Ltd. oversees the entire production process, ensuring that the cast, machined, and finished cases maintain strict tolerances. The result is a robust housing capable of enduring long-term cyclic stress without warping or misalignment of internal components. The case also functions as the mounting foundation for the detachable movement, ensuring precise engagement between the movement, impeller shaft, and flow chamber. Its structural integrity allows the meter to operate reliably in municipal pipelines, industrial water distribution systems, and high-pressure environments, maintaining accurate measurement across the entire DN50–DN200 diameter range.

The case of the WPH DN50–DN200 Horizontal Detachable Spiral Wing Water Meter is treated with advanced thermal spraying technology, providing a coating thickness and adhesion level twice that of traditional spray methods. This protective layer not only improves corrosion resistance but also enhances structural longevity under harsh conditions such as high humidity, chemical exposure, and buried installations. The coating adheres to the case surface with a dense micro-crystalline structure, providing a physical barrier against water, sediment, and environmental abrasion. Ningbo Water Cube Instrument Technology Co., Ltd. ensures that every meter undergoes rigorous quality testing, including pull-off adhesion assessments, thickness verification, and simulated salt spray exposure to confirm long-term reliability. The thermal sprayed coating reduces the risk of microfractures, which could otherwise compromise case rigidity or introduce dimensional inconsistencies. Internally, the protective layer prevents erosion of the chamber surface, preserving the precise alignment of the impeller and movement. This structural protection extends operational life and ensures that the meter continues to function accurately even in challenging installation environments. The coating’s durability reduces maintenance frequency, allowing for long-term cost efficiency and improved lifecycle performance without compromising measurement accuracy.

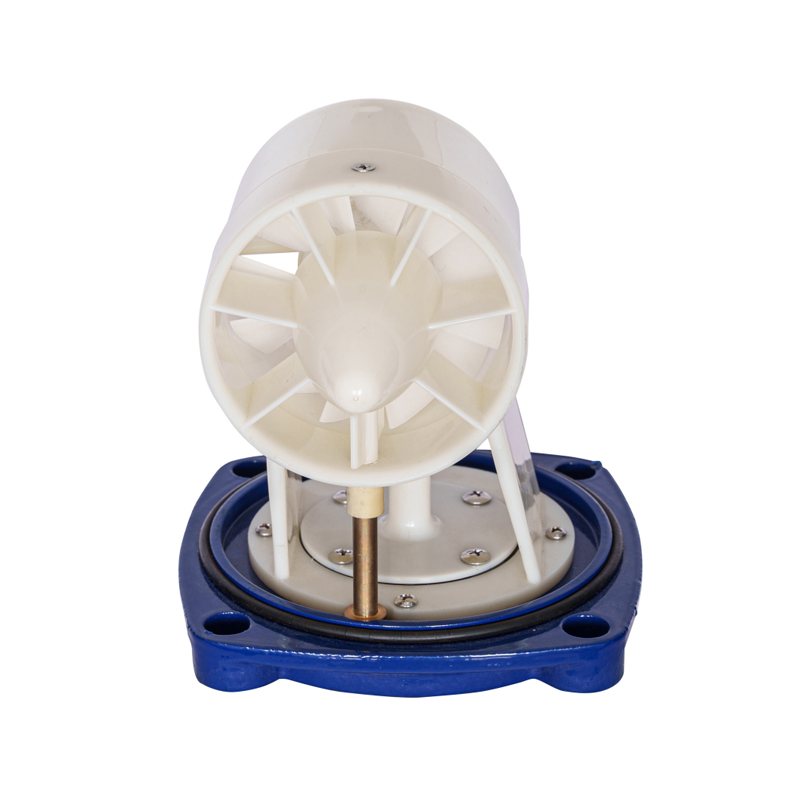

The internal flow chamber of the WPH DN50–DN200 Horizontal Detachable Spiral Wing Water Meter is engineered to minimize turbulence and optimize the interaction between the water and the impeller. Smooth internal surfaces, gradual curvature transitions, and non-obstructive entry and exit pathways ensure laminar or near-laminar flow even at variable velocities. This precise control of flow dynamics reduces mechanical resistance on the impeller, enhancing its responsiveness to changes in water flow and preserving long-term rotational stability. The spiral wing impeller features an advanced fluid dynamic floating design that balances torque distribution and minimizes bearing load while allowing early rotation at low flow rates. Ningbo Water Cube Instrument Technology Co., Ltd. integrates its in-house mold design and machining capabilities to produce internal channels with tight tolerances, ensuring consistent performance across multiple production batches. By aligning structural components with fluid mechanics principles, the meter achieves higher measurement accuracy, reduced wear on mechanical components, and improved energy efficiency in the flow system. The structural integration of the flow channel with the impeller and shaft reduces vibration, prevents misalignment under pressure fluctuations, and maintains repeatable measurement performance over the meter’s service life.

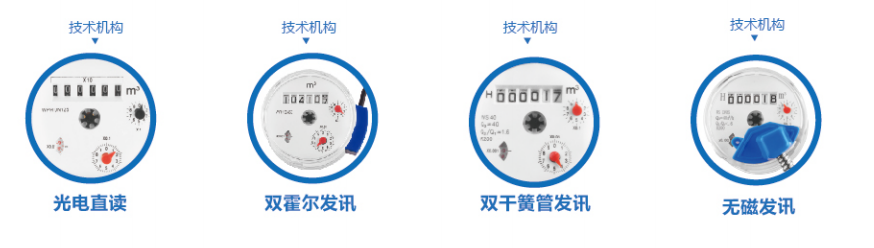

The detachable movement of the WPH DN50–DN200 Horizontal Detachable Spiral Wing Water Meter is engineered to maintain structural cohesion while allowing convenient maintenance, inspection, and replacement. The movement seating interface is precisely machined to ensure exact alignment with the central impeller shaft and casing, preserving measurement accuracy even after repeated servicing. This modular design minimizes the risk of misalignment or leakage, with reinforced mounting seats that absorb operational stresses and distribute loads evenly. Ningbo Water Cube Instrument Technology Co., Ltd. leverages its complete industrial chain, from design to assembly verification, to maintain strict tolerance control and ensure structural compatibility across components. The detachable structure allows for quick removal of the movement without disassembling the entire meter, reducing operational downtime and maintenance complexity. Structural support features, including bearing housings and anti-vibration components, maintain mechanical stability during service operations. This design approach ensures that both the case and the internal components retain their structural integrity, preventing mechanical fatigue and maintaining the meter’s long-term accuracy and reliability.

The case chamber of the WPH DN50–DN200 Horizontal Detachable Spiral Wing Water Meter is fully machined to achieve a high level of dimensional accuracy and structural consistency. Machining ensures uniform internal geometry, precise seating for the movement, and optimal clearance for the impeller. Ningbo Water Cube Instrument Technology Co., Ltd. performs strict quality checks at each production stage, verifying chamber tolerances, surface flatness, and alignment accuracy. This precision machining reduces mechanical friction, prevents rotational imbalance, and maintains consistent measurement performance even after movement replacement. The machined chamber enhances load distribution within the meter, supporting shaft and bearing assemblies during variable flow conditions. Structural consistency achieved through machining ensures that the meter performs identically across different installation environments, contributing to predictable calibration stability and long-term metrological reliability. The precise internal chamber geometry also enhances flow distribution, reducing turbulence and preserving impeller efficiency. Overall, the fully machined case chamber ensures that structural and functional performance are seamlessly integrated in a single, robust design.

عربى

عربى