Application Adaptability of the WS DN40 Pipeline Monitoring Water Meter for High-Demand Usage

High-demand water usage scenarios describe environments where usage patterns change frequently, flow intensity rises and falls unpredictably, and water consumption behaviors are influenced by building scale, industrial requirements, or system automation. The

WS DN40 Pipeline Monitoring Water Meter must operate with consistent performance across multiple conditions, including sudden consumption surges, prolonged high-flow operations, intermittent low-flow states, and various pressure levels generated by modern hydraulic systems. Such conditions appear in commercial buildings with multi-floor water distribution branches, industrial units where equipment cycles generate continuous demand, and mixed-use complexes where the mix of residential and commercial activities produces irregular water usage rhythms. The meter needs to maintain measurement stability when water networks experience turbulence, pressure oscillations caused by pump activation, or temperature variations that influence water density and flow dynamics. Usage unpredictability has increased as more buildings integrate smart appliances, automated cleaning systems, and water-intensive amenities. These changes require metering equipment capable of handling diverse operating behaviors without degradation in reading consistency. The WS DN40 model supports extensive adaptability because the internal movement, flow channel structure, and material configuration are shaped by the integrated engineering approach of Ningbo Water Cube Instrument Technology Co., Ltd., whose complete industrial chain allows adjustments at each manufacturing stage. This structure includes product design, mold development, precision injection molding, assembly, and verification. Since high-demand environments may involve hydraulic noise, air entrainment, or rapid valve closures, the meter must continue generating stable readings without drift. As a result, its application range expands beyond typical building installations toward more complex and intensive usage categories. In these scenarios, the WS DN40 meter supports accurate monitoring that benefits network planning, consumption diagnostics, and fair distribution of water costs. The adaptability of the meter emerges from coordinated engineering rather than single-component optimization, allowing us to deploy it in multiple advanced environments without operational limitations.

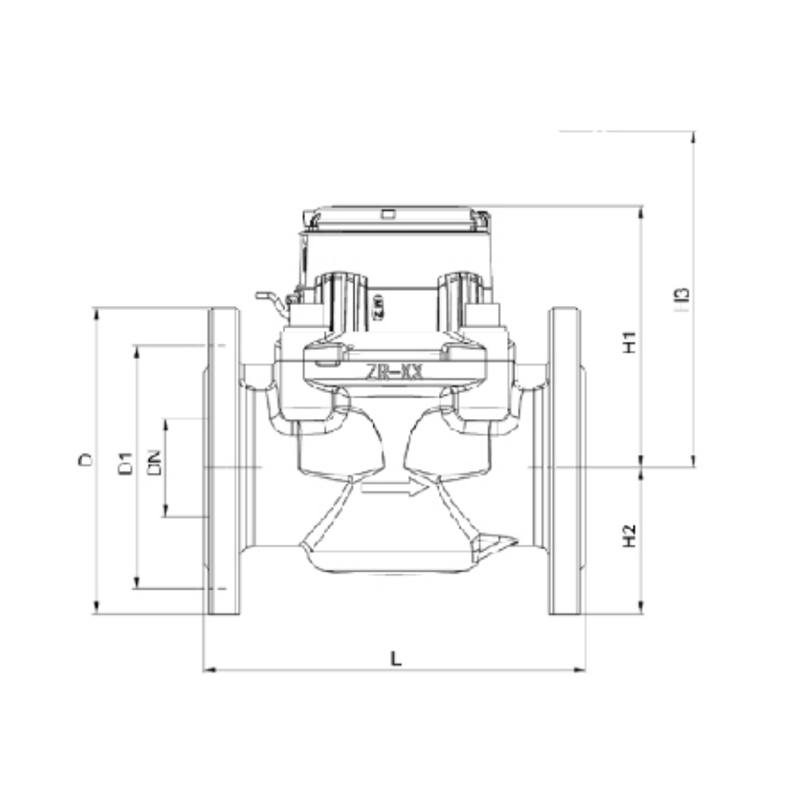

The WS DN40 Pipeline Monitoring Water Meter follows engineering principles that allow consistent behavior under demanding situations where hydraulic patterns shift rapidly. The internal design focuses on balanced flow interaction, controlled rotational behavior of the measurement movement, and reduced sensitivity to noise within pipelines. When high-flow water moves through a narrow channel, it may create vortices, acceleration zones, or intermittent turbulence. The meter incorporates flow-guiding structures that distribute velocity evenly around the measuring element, helping maintain smooth operational cycles even when usage intensity increases. The internal impeller is crafted through precision molding to minimize friction during rotation, and its geometry is shaped to sustain balanced torque regardless of flow direction changes associated with building-level pressure interactions. The supporting shaft and bushings are selected for durability, resisting wear produced by abrasive particles or chemical variations in water quality. Because high-demand environments introduce repetitive stress cycles, the meter housing and internal supports are reinforced to maintain dimensional stability. The manufacturing capabilities of Ningbo Water Cube Instrument Technology Co., Ltd. enable refinement of each structural detail, since the company manages the full process from mold manufacture to final verification, allowing design enhancements that support better mechanical reliability. The meter must also adapt to variations in installation layout, such as vertical or horizontal positioning, side-stream placements, and limited-space installations common in retrofit projects. The WS DN40 design maintains functional behavior across these orientations, preventing inaccurate readings due to gravity-induced imbalance. The flow channel design prevents debris accumulation and allows water to move smoothly through the measurement zone, reducing the possibility of clogging under continuous use. The engineering principles supporting this meter concentrate not on isolated features but on an integrated interaction of movement precision, structural robustness, materials that withstand long-term hydraulic exposure, and production methods that maintain close tolerances.

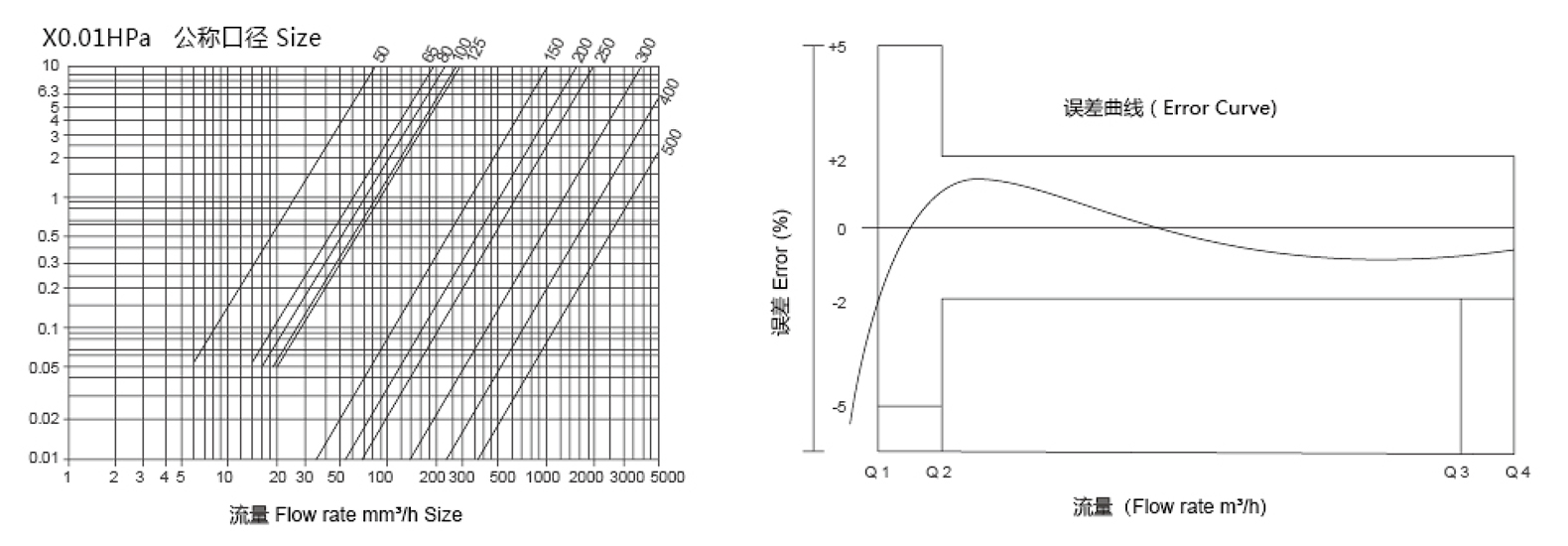

The WS DN40 Pipeline Monitoring Water Meter incorporates sensitivity optimization techniques to handle broad flow ranges encountered in real environments. In buildings, flow may drop to minimal levels during nighttime or rise sharply during morning or evening peaks. Industrial systems exhibit different patterns where machinery cycles create short bursts of high-flow followed by stable mid-flow intervals. Sensitivity optimization aims to ensure accurate readings across these variations. The measuring movement must rotate reliably even when flow is very low, as low-flow accuracy influences consumption calculations significantly in multi-tenant settings. The meter uses an impeller profile shaped for smooth activation at low velocities, reducing the threshold at which rotation begins. This design avoids dead zones where flow is present but insufficient to overcome mechanical resistance. Under high-flow conditions, sensitivity adjustments prevent overstimulation of the movement, ensuring it continues rotating in a controlled manner without slipping or generating oscillations that distort readings. The manufacturing precision achieved by Ningbo Water Cube Instrument Technology Co., Ltd. supports consistent alignment of internal components so the impeller can sustain predictable motion even at high speeds. The materials chosen for sensitive components resist deformation under repeated high-velocity impact, preserving long-term calibration. Sensitivity optimization also helps the meter manage transient flows produced by valve changes, pressure boosters, or pump cycles. The meter stabilizes rapidly after disturbances so that monitoring data remains reliable. Water quality fluctuations introduce additional sensitivity challenges. When debris flows through pipelines, the meter must maintain responsiveness without mechanical jamming. Its geometry encourages particles to pass through without adhering to the chamber. The design supports stability when minor air pockets enter the system, preventing unnecessary measurement fluctuations. Across residential, commercial, and industrial contexts, sensitivity optimization increases the meter’s capacity to represent actual consumption faithfully. Combined with stable structural engineering, this allows accurate monitoring under constantly shifting conditions typical of high-demand usage.

In high-demand usage environments, measurement accuracy directly influences billing outcomes, operational evaluations, and dispute resolution. The WS DN40 Pipeline Monitoring Water Meter is designed to produce stable readings regardless of variations in daily consumption rhythms. Accurate measurements support transparent billing in multi-tenant buildings, ensuring each occupant is charged according to actual usage. In commercial or industrial settings, water usage is often tied to cost-allocation systems or operational planning metrics, making measurement precision necessary for financial reliability. The WS DN40 employs a tightly calibrated movement built through the refined manufacturing chain of Ningbo Water Cube Instrument Technology Co., Ltd., allowing consistent alignment between flow input and rotational output. Calibration within the production process ensures reading repeatability across different units. Since high-demand scenarios amplify potential errors if a meter drifts from its intended accuracy, structural stability plays a central role in preventing deformation or friction increase that may affect measurement consistency. Billing impact extends beyond financial fairness. Reliable measurement supports consumption analysis that allows building managers or utility providers to understand usage profiles, detect abnormalities, and plan infrastructure upgrades. For instance, continuous high-flow conditions may indicate leakage or inefficient equipment operation. Accurate measurement under these conditions allows early detection. Buildings with automated water management systems rely on meter accuracy to guide system behavior such as pump scheduling, storage tank balancing, or equipment shutdown thresholds. In industrial environments, measurement accuracy helps control production processes that depend on consistent water supply. If a meter provides distorted readings, it may lead to errors in production calculations or regulatory reporting. The WS DN40 meter maintains accuracy across long operational cycles through durable materials, smooth rotational mechanics, and resistance to wear. Its predictable response during sustained high-flow periods ensures reliable data for billing audits and operational assessments. As a result, the meter contributes to transparent cost distribution and dependable resource monitoring without relying on external compensatory mechanisms.

Industrial and commercial usage environments often generate constant water demand with periodic surges resulting from equipment cycles, cleaning operations, cooling demands, process mixing, or supply line refills. The WS DN40 Pipeline Monitoring Water Meter adapts to these conditions through structural resilience, flow-handling capacity, and durable internal mechanisms. Industrial pipelines may contain variable water purity levels influenced by sediment, chemical traces, or operational debris. The meter’s internal design allows water to pass through without clogging, with smooth surfaces that discourage buildup. The precise molding processes performed by Ningbo Water Cube Instrument Technology Co., Ltd. ensure tight tolerances that support consistent flow distribution. Commercial environments such as hotels, retail complexes, or mixed-use buildings experience periods where demand rises sharply when occupants engage in synchronized activities. The meter maintains a consistent rotational pattern during these surges, avoiding measurement saturation or rotational instability. When building systems trigger automated processes like irrigation, cooling tower refills, or cleaning cycles, the WS DN40 adapts to sudden changes without requiring stabilization time. In industrial settings, mechanical vibrations from nearby equipment often affect pipeline behavior. The meter is reinforced to maintain internal alignment under such conditions, preserving long-term accuracy. Its adaptability extends to installation flexibility. Many industrial and commercial facilities present constrained spaces where meters must be installed at non-ideal angles. The WS DN40 maintains consistent behavior whether installed horizontally or vertically, as the internal movement has been engineered to avoid gravity-related imbalance. Another aspect of adaptability involves water temperature variations. Industrial machines can elevate water temperature, while some commercial systems introduce cooler water during peak conditioning operations. The chosen materials resist expansion or contraction stresses induced by temperature shifts. Overall, the meter supports an environment where demand intensity interacts with operational factors such as vibration, debris, temperature, and pressure variation, performing reliably across extended use cycles.

عربى

عربى